- Smart Factory

- Solutions

- Products

- About Erowa

- Shop

-

Your watch list

0

-

No articles in the watch list

-

EROWA Robot Compact 150

Smart automation for all manufacturing technologies

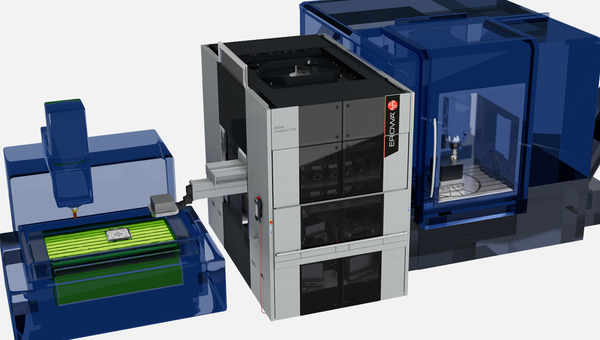

The new EROWA Robot Compact 150 impresses with its wide range of functions and a transfer weight of up to 150 kg.

It is the perfect automation solution for flexible loading of up to two production machines for all processing technologies - from milling to eroding.

Thanks to its innovative design, the loader offers an impressive magazine density with a small footprint.

The robot for various processing technologies

An autonomous and flexible production cell. The EROWA Robot Compact 150 loads a milling center and a die-sinking EDM machine with little space requirement.

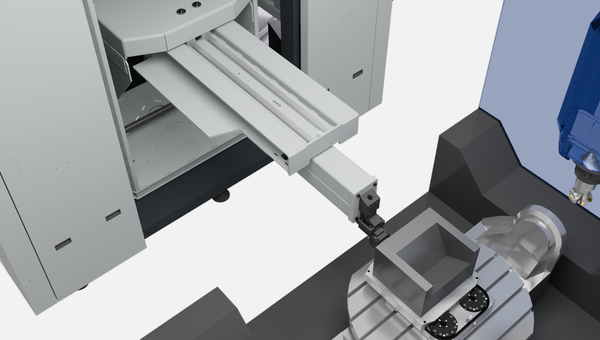

Long reach

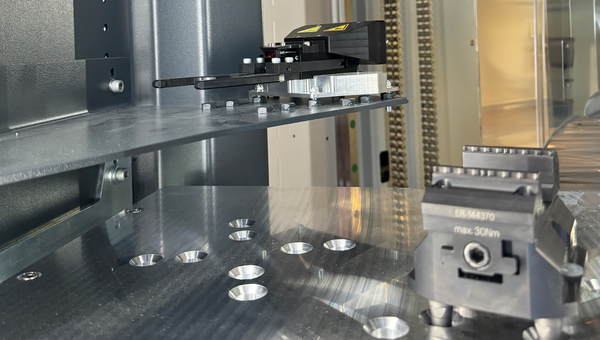

The two independent drives of the X-axis enable compact magazine handling and high magazine density. This also enables a long reach and a minimal interfering contour to the machine.

150 kg transfer weight

Even large EROWA MTS 400 pallets with a transfer weight of up to 150 kg and a workpiece height of up to 400 mm are loaded precisely onto the machine.

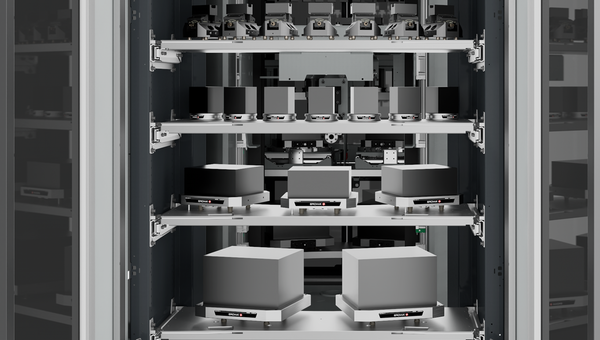

Variable magazine levels for different pallet sizes

Over 500 EROWA pallets with different system sizes can be stored in the magazines. The magazine levels can be set up exactly as required.

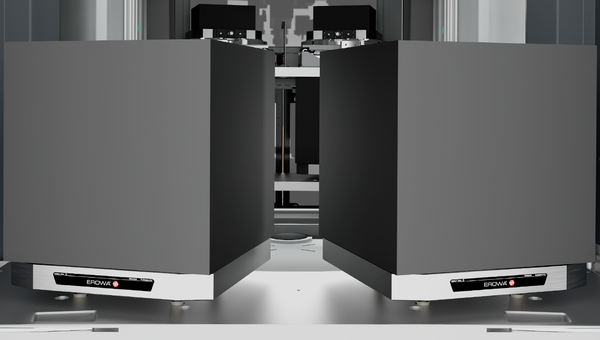

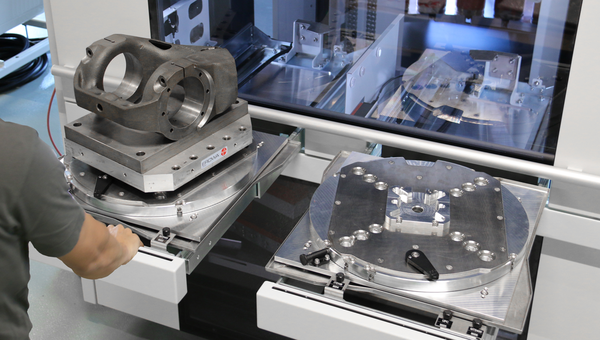

Ergonomic loading station for heavy workpieces

The optional loading station can be integrated to save space. It enables large and heavy workpieces (UPC and MTS pallets) to be set up at an ergonomic height while the robot is working. An indexing system (4x90°) prevents the pallet from engaging in the wrong position and locks it automatically when it engages.

Pull-out magazine levels

Easy loading and unloading by pull-out magazine levels. The pull-out is triggered by the integrated handle positions.

Quick overview of all magazine positions

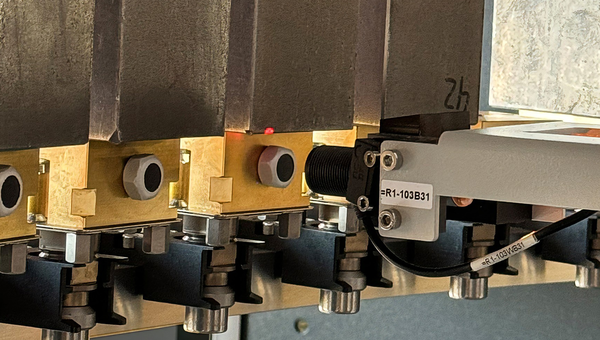

The EROWA EWIS™ chip identification system (option) is based on RFID technology. It enables the unique identification of pallets and electrode holders fitted with EWIS chips in the robot magazine.

Space-saving gripper shelves

The gripper shelves can be attached to the magazine side walls to save space. Only individual magazine slots are blocked so that no entire shelf is used as a gripper shelf.

All data at a glance

The EROWA process control system JMS 4.0 connects all data and controls the entire production process. Due to the automated data flow and real-time monitoring of your production processes, JMS 4.0 provides the basis for a seamless workflow that revolutionizes the production process.