Consistent identification

Clear identification in every production step

With JMS 4.0, it is always clear which workpiece is at which place in the process at which time. The pallets of workpieces provided are uniquely labelled with a chip, QR code or barcode. At each station in the production process, unique identification can be guaranteed by the central process control system.

Manual identification (RIFD)

The manual assignment of objects using an RFID chip ensures unique identification for the reliable management of workpieces and electrodes. This unique assignment of raw materials and pallets prevents errors and ensures that the machine can be set up quickly.

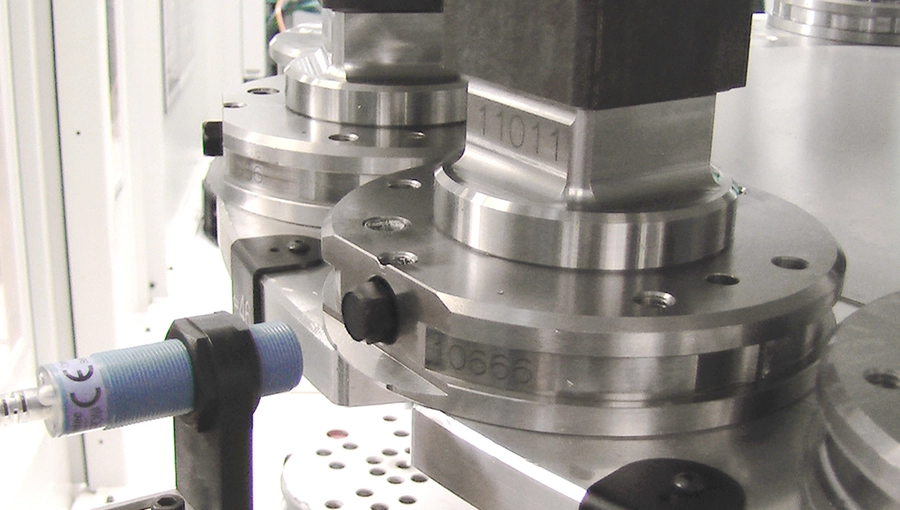

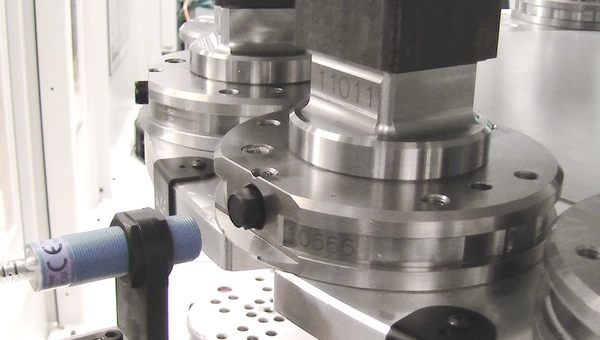

Automatic identification (RIFD)

Identification using RIFD chips can also be automated. When a magazine is loaded with workpieces or electrodes, the magazine is automatically identified by sensors and the information is transferred to the process control system. Automatic identification guarantees a high level of process reliability.

QR code and barcode

The data matrix code (QR code) and the barcode enable you to manage milling tools, tool holders and parts list documents with process reliability. In conjunction with our intelligent interfaces to the machine controls, we create security and transparency.