EROWA MTS

The versatile zero point tooling system

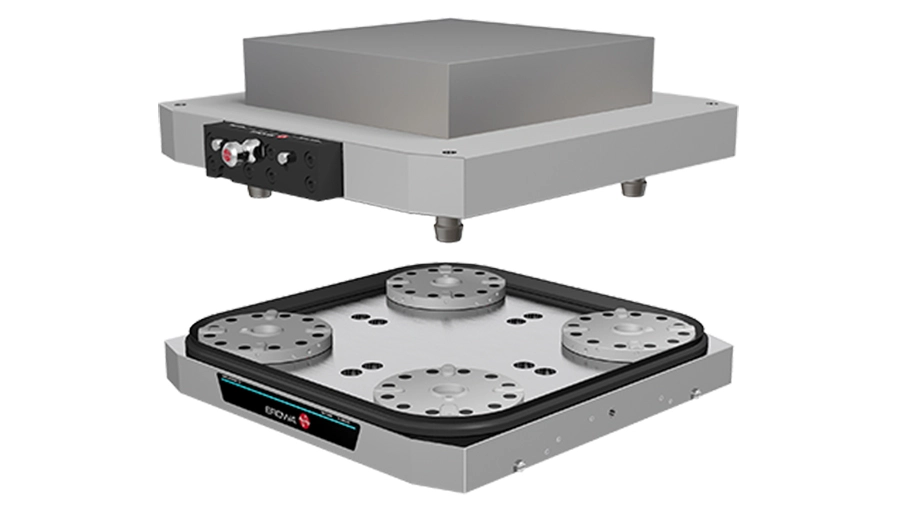

The EROWA MTS (Modular Tooling System) is a flexible tooling system. The maximum workpiece size is exclusively determined by the machine capacity.

Whether you require single palletization with an MTS chuck or multiple palletization with several MTS chucks or base plates – all combinations are possible.

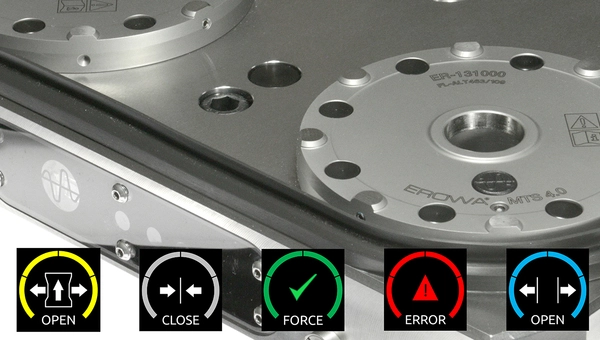

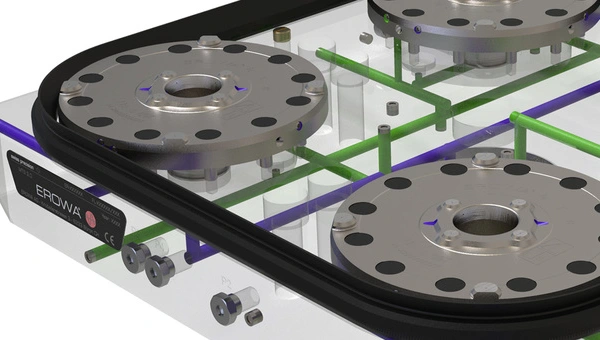

EROWA MTS 4.0 - The zero-point tooling system with wireless digital status monitoring

For highest process reliability

Integrated into the machine control system, MTS 4.0 provides comprehensive information and status displays on the condition of the MTS 4.0 chucks in real time.

MTS 4.0 meets the increased safety standard according to ISO 13849

PLd- Cat 3.

Ready for Industry 4.0

The data signals of the MTS 4.0 chucks are sent wirelessly to a receiver integrated in the machine.

Electronic monitoring enables a completely new range of evaluation options: Proactive maintenance, precise process analysis, and extended monitoring options.

Simple control

Only two pneumatic lines are required to control the MTS 4.0 base plate: Opening and reclamping (optional: cleaning air for automation).

Power is supplied autonomously via the integrated battery.

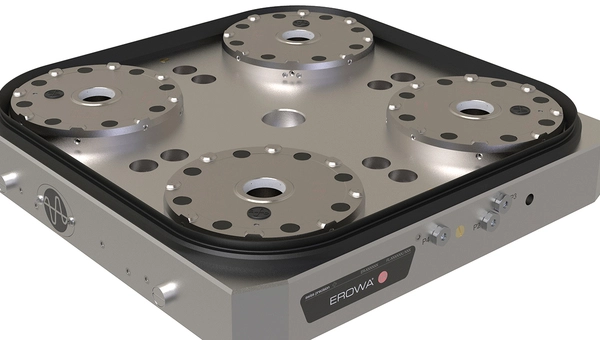

MTS 3.0 - Maximum safety in the machining process

Safety first

MTS 3.0 meets the highest safety standards. Thanks to the integrated monitoring functions, the machine quickly and clearly detects whether the clamping system is ready for machining.

Due to the self-locking mechanism, the chucks remain 100 % securely clamped even in the event of a pressure loss.

Everything under control

Before machining starts, the presence of the chucking spigot and the chuck locking are checked via the integrated air circuit.

If the combined check is fulfilled, authorization for machining is given. This means: All chucks are correctly clamped, all clamping spigots are present.

Patented technology

The technical implementation of MTS 3.0 is unique, patented and certified. The clamping system fulfils the specifications of ISO standard

13849 PLd-Cat 3.

EROWA MTS - The zero point tooling system for your production

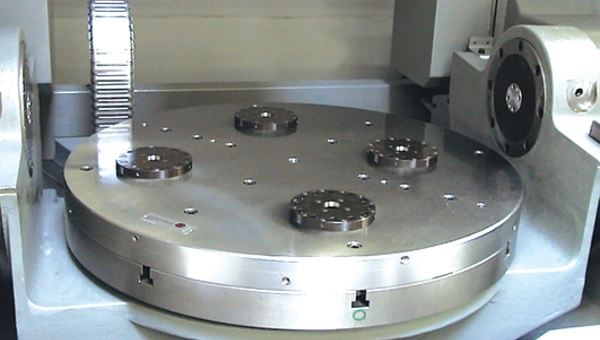

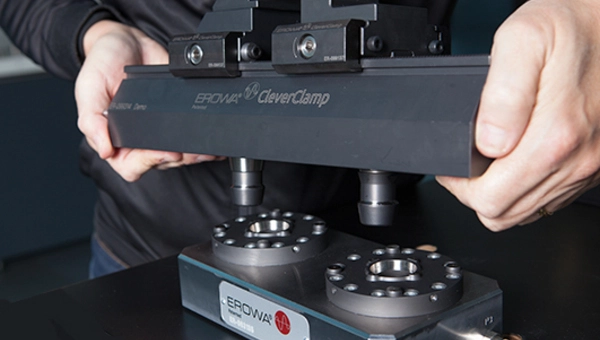

Modular and universal clamping

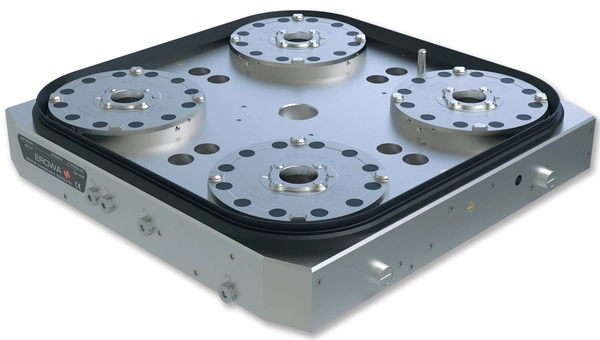

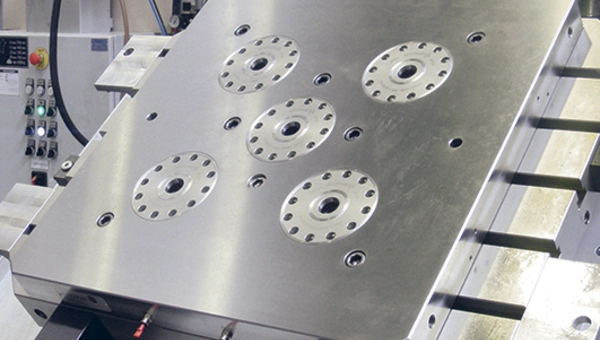

MTS base plates are the flexible and precise interface for single or multiple palletization.

MTS base plates are available in various versions – with 1, 2, 4, 6 or 8 MTS chucks, depending on the model. We would also like to advise you on customized versions.

Minimizing setting-up times

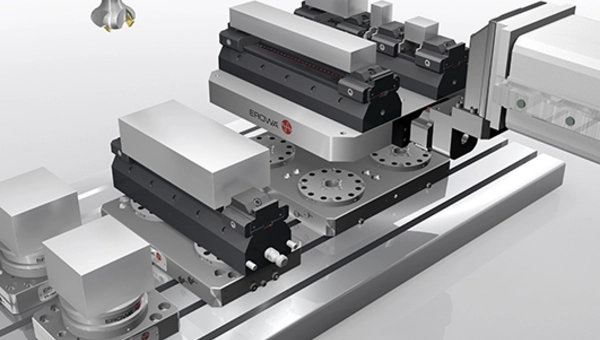

Workpieces and fixtures are palletized so that they can placed on the machine when required without any further setting up. On the machine, the MTS palletizing system holds them in position with precision and stability. Further jobs are prepared outside the machine.

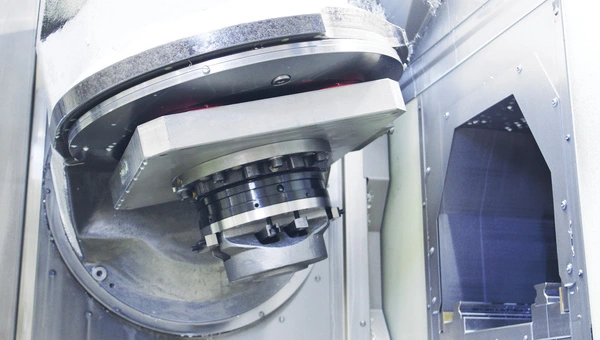

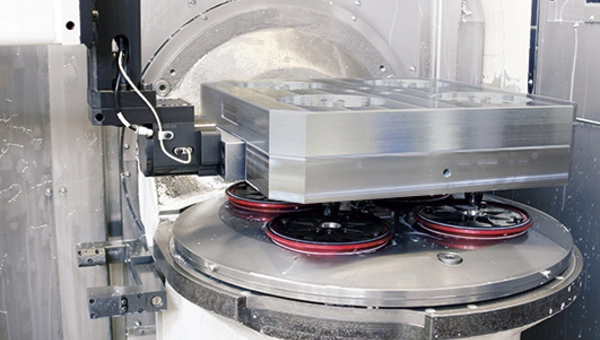

Automation

The MTS system is ideally suitable for automated pallet change.

When workpieces are changed, the contact surfaces of the chucks and chucking spigots are cleaned automatically. The MTS pallets are positioned neatly and with precision.

Low construction height

The low construction height of the EROWA MTS tooling system leaves a great deal of space for workpieces.

MTS chucks are fitted to the machine table or directly integrated in it.

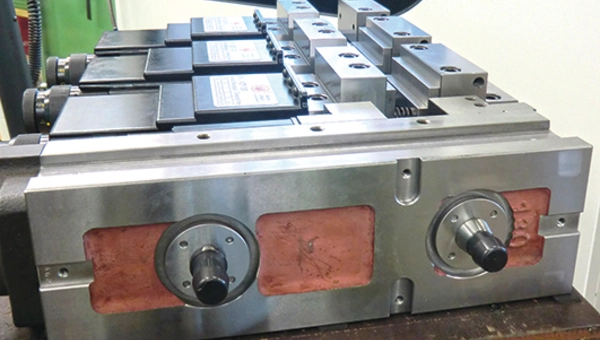

Making use of existing equipment

Existing vises, gauges and fixtures are equipped with chucking spigots or palletized. This immediately makes them universally integrated in the MTS system.

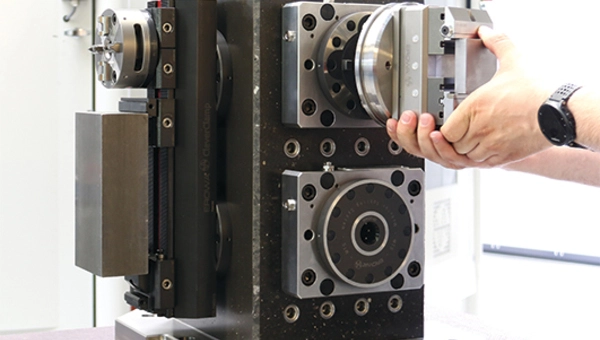

Making optimal use of working space

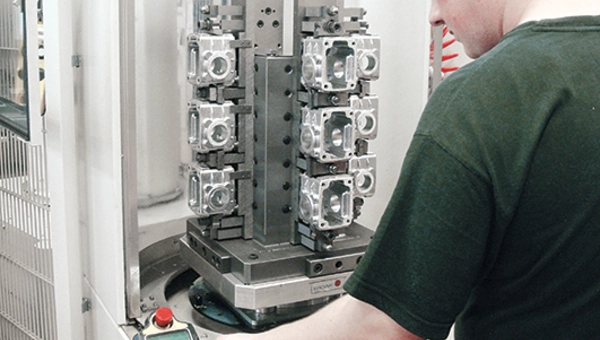

The EROWA mineral cast tombstone provides a great deal of space for the simultaneous setting up of different workpieces. The entire working space of the machine is optimally exploited through the use of a tombstone.

At a glance - The different EROWA MTS palletizing systems

EROWA MTS 81 - Small size, high clamping force

MTS 81 is used wherever the available space is limited. Precise positioning of the pallets and high clamping force included.

EROWA MTS - The universal interface

The proven and versatile zero point clamping system enables pallet change of the workpiece carriers within seconds with a repetition accuracy of < 0.005 mm.

The modular design of the clamping equipment allows an almost unlimited combination of all components.

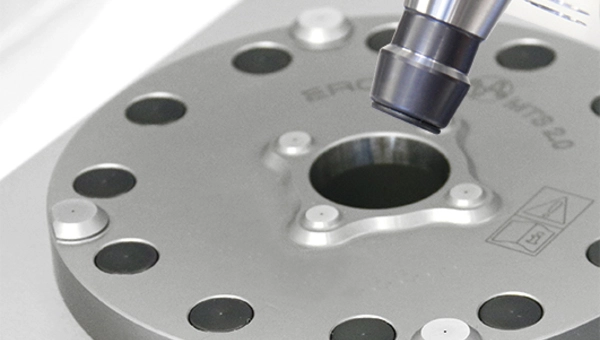

EROWA MTS 2.0 - For highest demands

The zero point clamping system with pioneering functions. Ready for Industry 4.0. Real-time status display with maximum process reliability.

The centering and compensating pins position and and center the workpiece carrier precisely in the MTS 2.0 chucks with < 0.003 mm.