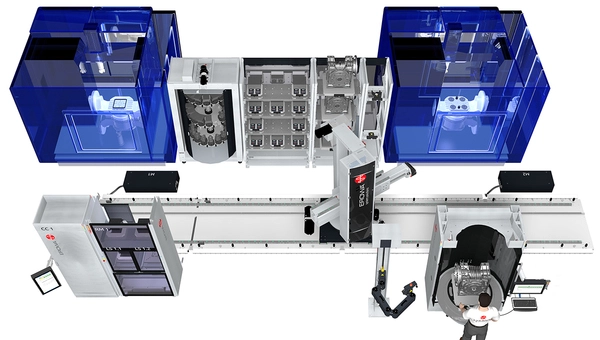

EROWA Robot Dynamic 500

Automation for heavy parts

The EROWA Robot Dynamic 500 is a flexible loading device for serve processing machines with large and heavy as well as small and light workpieces.

The transfer unit can be equipped with one or more magazines; and on a rail up to 30 m long it becomes the "EROWA Robot Dynamic 500 Linear" and loads up a dozen machines.

Up to 500 kg transfer weight

Palletized workpieces of up to 500kg in weight and, for instance, 800×800×500mm in size can be loaded onto the machine tool safely and with precision.

Besides the focus on heavy workpieces, the robot can also reliably transport lightweight pallets.

Exchange gripper system

The EROWA Robot Dynamic 500 has an exchange gripper system with which EROWA pallet and system sizes can be handled.

The robot switches to the relevant system according to the jobs it has been assigned. This means that there are no obstacles in the way of mixed and flexible manufacture.

The increase on effectiveness with this flexibility is astounding

Modularly extendable at any time

Do you need more magazine positions? Do you want to serve a second machine? Do you want to integrate a measuring machine or a loading station?

No problem: the robot system can be adapted to current requirements at any time and be modularly extended to a rail length of 30m.

Suitable magazine positions

Magazines are available as rack and rotary versions which can be configured for all EROWA tooling system pallets.

While rack magazines are suitable for large and heavy pallets, rotary magazines provide ample storage positions for smaller workpieces.

Practical loading station

A loading station is avaiable to simplify setting up and the preparation of heavy and large workpieces.

This is where the palletized workpieces are prepared for the next job: the operator has the robot collect the prepared job by pressing a button and placing it on a free position in the magazine.

Of course the JMS 4.0 Process Controller will monitor and keep track of all pallets at all times.

Cell management

EROWA's JMS 4.0 process control system provides the machine operator with all the relevant information and various planning aids, updated and online, at all times.

This is one of the requirements for the flexible and automatic manufacture of small series and one-off parts.

RFID Chip reader

The reader ist integrated in the horizontal transfer axis. It is always there when you need it.

Railsystem up to 30 m length

Stable system in spite of its low profile design. The segments are joined up to the required length.

Heavy duty swivel axis

No matter if the pallet needs to be inserted horizontally (table) or vertically (tomb-stone); With the 400 kg capacity swivel axis, the orientation makes no difference to the robot.